The auto industry is no stranger to challenges. Throughout the years it’s weathered recessionary periods, environmental concerns, changes in driving behavior, new international players, and more. It’s a consistently tough market. Those who work in and serve the industry are constantly working to keep up.

And that was before the pandemic hit (and hit the global economy, too). The marketplace, in a word, is “challenging.”

There are some bright spots of course. Aging fleets need replacing, essential workers need reliability, and more consumers are embracing a DIY aesthetic. One thing is for certain, the automotive and aftermarket industry will continue to be a resilient and essential part of the economy. And now is the time to re-set, and prepare for what comes next.

From a product content standpoint, here are four suggestions for how to prepare for the future and overcome some product content challenges.

1. Reduce or eliminate manual data processes

Back when there was a hybrid of enterprise and local data management systems, it was more common to use manual processes to manage product information. With spreadsheets or standalone databases to input data, edit, or add industry codes and images, it was a workable situation. But at some point in the last few years, much (if not most) of the industry product inventory is managed through larger, more integrated systems, with specific requirements. And using manual processes across internal workstreams is roadblock to item completeness and accuracy, especially where different teams are using different sources.

2. Align business issues and systems across internal groups

Historically, technology systems were leveraged for single business purposes – Operations had their system, which was different from Marketing, or Sales… These systems often have disparate forms of data and tools, which causes data to get out of sync. In fact, companies invest an average of 25 minutes per item, per year manually cleansing out-of-sync item information. A company with 10,000 SKUs could spend over 4,000 manual hours – 2 full time employees – every year just cleaning out bad product data. When departments are working with isolated processes, they often work against each other by creating inefficiency.

3. Invest in quality data

As bad as having multiple systems and individuals managing product information can be for data alignment, another element is simply the quality and consistency of the data itself across an organization. Gartner estimates that low quality data costs companies approximately $15 million in losses per year. This is not surprising. Creating, managing, auditing, and syndicating product content is a complex process, and when it becomes a department’s second most important priority (behind driving the actual business plan), quality can suffer.

4. Align data structure to Receiver requirements

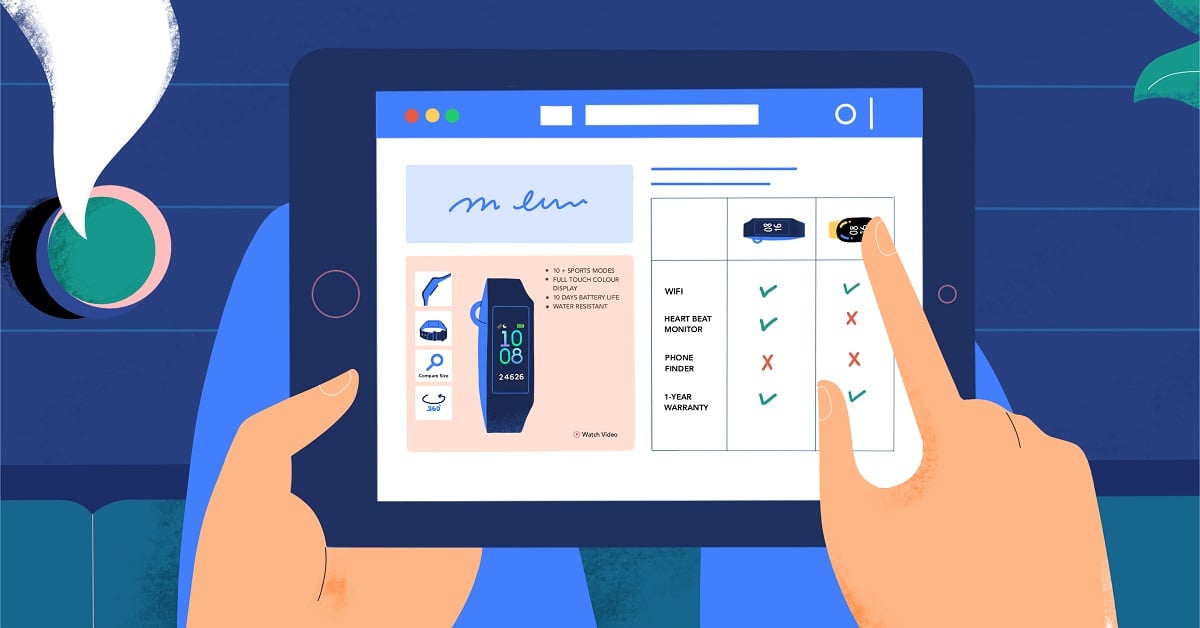

Perhaps the most important aspect of data management is preparing it and distributing it to the recipients who need it to sell your products. Of course, all retail requirements are different, and even with industry standards such as ACES, PIES, or GDSN, there is also the need to ensure the data works for them. Each retailer has a desire to be differentiated to the consumer – both online and in-store, and the way they present products demands they build a differentiated experience to help convert at the time of purchase.

Simplify with Syndigo

Syndigo platform to address these key business issues. Rather than requiring suppliers to build or resource multiple systems to gather different product content for varying uses, Syndigo’s vision is to create an end-to-end solution that simplifies and integrates product content uses into a single platform solution.

Syndigo allows automotive aftermarket suppliers to efficiently publish clean, consistent data that meets receiver requirements as well as ACES and PIES needs. We keep up with industry standards and validate data in real time against customizable spelling and grammar dictionaries, to ensure better accuracy and validity. In addition, our taxonomy experts help to ensure that product content is properly cross-referenced to ensure that no matter the system or configuration, the items are accurately input and displayed.

One effective tool to ensure your content is both usable and flexible is CXH’s capabilities with asset transformations – in other words, the ability for product images to “shift on the fly” to meet different system or user needs. This integrated Digital Asset Management capability that can truly save time internally while ensuring consistency across different platforms.

Finally, it cannot be understated: a modern PIM is not complete without actual syndication to receivers, designed to their templates and delivery standards. Syndigo is recognized as a leader in true integrated syndication with receivers, ensuring the best possible transfer of your content through the ecosystem. Suppliers should not have to create multiple files for each receiver – once a delivery schedule is confirmed, Syndigo handles all ACES, PIES and GDSN delivery submissions.

Keeping up with today’s eCommerce requirements is daunting. Syndigo can help automotive parts suppliers and retailer receivers stay in sync with product content that ensures the best accuracy and data transparency on the market. With CXH, your product information management, digital asset management, syndication and analytics are in one place, delivering a more integrated and effective content experience overall.